Lightning McQueen

As a project for Prototyping and Fabrication, my team partner and I were prompted to build a bluetooth motorized chassis. This course taught skills in designing, prototyping, and fabricating for physical objects, including 2D and 3D modeling and fabrication, basic electronics, lasercutting, and 3D printing.

Timeline:

June - July 2019

Tools:

Adobe Illustrator, Arduino, Universal VLS

Team:

Diana Fan

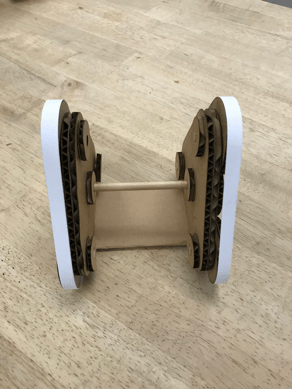

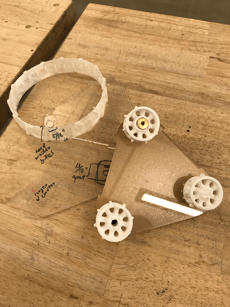

Cardboard prototype:

We wanted to create movement through using a rubber tread around the outer planetary gears and motorizing the central gear. We believed that the triangular shape would work best for lightness, stablility, and speed.

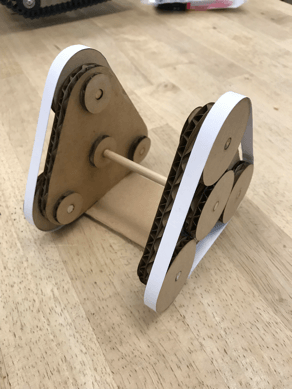

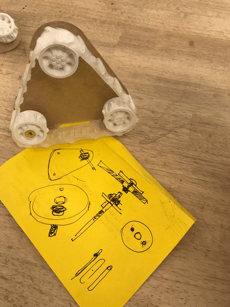

Motorized chassis prototype:

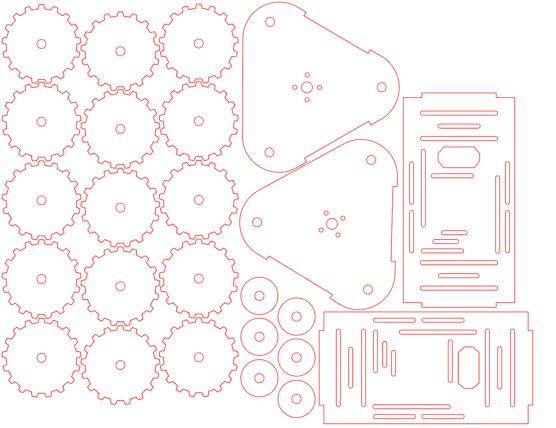

Following our initial cardboard prototype, we laser cut .25” plywood and attached our motor to the center gear, which was used to spin the outer gears. We used a gear piece from another commercial motororized chassis, and replicated this gear by laser cutting and stacking the plywood to get a perfect fit. For the body of the prototype, we cut multiple slots out so we could find the best fit and placement for the BLE feather and batteries.

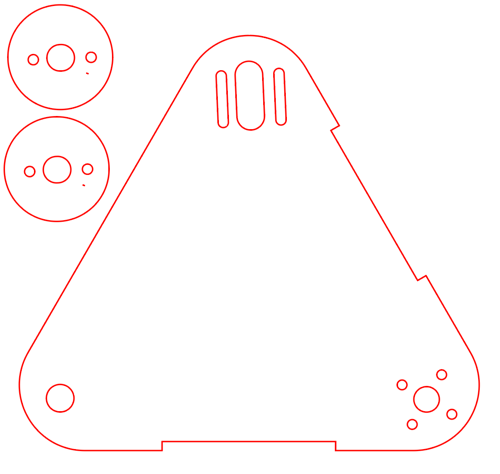

Adobe Illustrator Files:

Final iteration:

We 3D printed wheels and treads using flex, and made the rest of the body using clear acrylic. It took multiple adjustments to find the perfect fit for the wheels and tread, by making sure there was not too much or too little slack. We made the top hole adjustable so we could slide the wheels on and off, and created washers to support the wheels onto the body. Using the same motors and BLE feather, we assembled the rest of the body similar to the wooden prototype, and we made cases for each of the components with easy access to switch them in and out.

Final prototype: